Ndodo Zolimba za Carbide

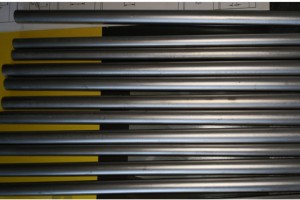

![]() Kuyamba kwa Solid Carbide Ndodo

Kuyamba kwa Solid Carbide Ndodo

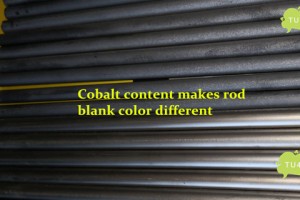

Ndodo yolimba ya carbide imapangidwa ndi tungsten carbide, binder chitsulo cobalt ndi zina zowonjezera zomwe zimangowonjezeredwa monga chilinganizo chimafuna, kudzera mu zinthu zosakaniza, extruding, pre-sinter, mawonekedwe osintha mawonekedwe kenako sintered mu kuthamanga pang'ono. Ndi otchulidwa mkulu kuuma, mphamvu mkulu, mankhwala khola, koyefishienti kuwonjezeka otsika, magetsi ndi kutentha kuchititsa, ndi sintered tungsten carbide ndodo chimagwiritsidwa ntchito m'dera kupanga mafakitale Mwachitsanzo, kuti kubowola yaying'ono makampani PCB, elekitirodi bala mu gulu kuwala makampani, kubowola, kubowola katundu, nsonga, pusher, kuvala mbali zosagwira mwatsatanetsatane, CNC reamer ndi masamba okhala ndi dzenje lozizira pamakampani opanga.

Monga depo ya carbide, fakitale yachitsulo ya Toonney tungsten imapanga mitundu ingapo ya aloyi ya tungsten kuphatikiza ndodo zolimba, ndodo zokhala ndi dzenje lowongoka / lozungulira, ndodo zojambulidwa malinga ndi zomwe makasitomala amafuna ndi T zopangidwa ndi zina zambiri.

Ndodo zolimba za tungsten carbide, zopanda zotsekemera mkati. Tili ndi makalasi 10 a fomula yogwiritsidwa ntchito kwambiri, mwachitsanzo, ndodo za pobowola yaying'ono ya PCB, yodulira yaying'ono, mpeni wa carbide, kuboola kwa aloyi zotayidwa, aloyi wamkuwa, aloyi wazitsulo ndi; wolfram carbide ndi zina. Timalamulira mosamalitsa mtundu uliwonse munthawi yofunikira, titha kunena kuti zabwino ndi chimodzi mwazabwino zomwe zimatipangitsa kuyimirira pantchito iyi.

Wolfram carbide: Wolfram carbide ndi gulu lopangidwa ndi wolfram ndi carbide. Ndi kristalo wakuda wamtundu wakuda wonyezimira wonyezimira, womwe kuuma kwake kuli kofanana ndi diamondi.Wolfram carbide ndi woyendetsa wabwino wamagetsi ndi kutentha, sangathe kusungunuka m'madzi, hydrochloric acid kapena sulfuric acid, koma mosavuta kupasuka mu njira yosakanikirana ya nitric acid ndi hydrofluoric acid. Wolfram carbide wosalimba ndi wosalimba, koma kuwonjezera titaniyamu kapena cobalt ndi sintered, kulimba kwake kudzakhala kwakukulu kwambiri. Wolfram carbide amatchedwanso tungsten carbide.

Chitsulo cha Tungsten / chachitsulo cha Tungsten:Tungsten amatchedwanso wolfram, mtundu kwambiri wa tungsten chitsulo ntchito mafakitale ndi tungsten carbide. Fakitale yachitsulo ya Toonney idapanga ndodo zolimba za carbide kwazaka zambiri ndipo imakhala ndi mbiri yabwino kunyumba komanso kunja.

Zolemba Zambiri: Chikwama cha pulasitiki, kenako chotetezedwa ndi thovu, pamapeto pake kupita ku katoni yakunja.

Zitsanzo Zofunika:Ndodo zolimba za carbide zomwe zitha kupezeka pazomwe timapeza pafupipafupi, zitha kuperekedwa ngati zitsanzo zaulere. Pazitsulo zolimba za carbide zokhala ndi makasitomala osasamba omwe amafunikira, adzapatsidwa. Zachidziwikire, makasitomala amafunika kulipira ndalama zotumizira. Kawirikawiri, nthawi kutsogolera zitsanzo adzakhala mkati mwa masiku 7working.

Posachepera Order Kuchuluka: Palibe mitengo yocheperako yazitsulo zolimba za carbide koyambirira koyeserera. Koma pa dongosolo lachiwiri, kuchuluka kwathunthu kwa ndodo zolimba za carbide sikuyenera kukhala ochepera 1000 USD.

Nthawi yoperekera: Masiku 7-15 ntchito

![]() Kudula Zida Gulu Gulu ndi Ntchito

Kudula Zida Gulu Gulu ndi Ntchito

| Kalasi | Co% | Mbewu Siz (μm) | Kuchulukitsitsa (g / cm3) | Kulimba (HRA) | TRS (N / mm2) |

| TU90 | 9.0 | 0.2 | 14.35 | 94.1 | 5200 |

| TF06 | 6.0 | 0.6 | 14.81 | 93.1 | 4000 |

| TU06 | 6.0 | 0.4 | 14.8 | 94.3 | 4600 |

| TU08 | 8.0 | 0.4 | 14.52 | 93.5 | 4800 |

| TU08S | 8.0 | 0.3 | 14.5 | 93.6 | 5000 |

| TU40 | 10.0 | 0.8 | 14.4 | 91.7 | 4600 |

| TU40F | 10.0 | 0.6 | 14.45 | 92.3 | 4600 |

| TU40S | 10.0 | 0.5 | 14.5 | 92.5 | 4800 |

| TU44 | 12.0 | 0.4 | 14.1 | 92.6 | 4800 |

| TU25 | 12.0 | 0.6 | 14.06 | 92.5 | 4200 |

| TU45 | 13.0 | 0.3 | 13.95 | 92.7 | 4800 |

| TU55 | 13.0 | 0.3 | 13.92 | 92.6 | 4800 |

![]() Ntchito Yovomerezeka

Ntchito Yovomerezeka

| Kalasi | Ntchito yovomerezeka |

| TU90 | Pazida zodulira zida zakuthambo (HRC65-70), mitengo yolimba ndi odulira apamwamba. Zabwino kwambiri pazomata zodula 316L zosapanga dzimbiri |

| TF06 | Pazida zodulira machining aluminiyamu ya magnesium, graphite ndi fiber. |

| TU06 | Kwa PCB yaying'ono-kubowola ndi kumaliza makina opangira zida zazitali kwambiri. |

| TU08 | Kwa PCB yaying'ono-kubowola, wodula mini mphero. |

| TU08S | Pobowola yaying'ono ya PCB, zida zodulira zida zomaliza zotsekera (HRC60-65), 316L chitsulo chosapanga dzimbiri, pepala lazitsulo lazitali kwambiri komanso pepala lamoto la silicon. |

| TU40 | Pakuti pobowola wamba wamba, mapeto mphero ndi kukhomerera kufa. |

| TU40F | Pabowola wamba pobowola, kumapeto kwa makina opanga titaniyamu, chitsulo chosapanga dzimbiri komanso chitsulo chakuda. |

| TU40S | Pazida zodulira Machining 316L zosapanga dzimbiri, zopangira zabwino kwambiri zazingwe zozungulira. |

| TU44 | Pazida zodulira matani aloyi a titaniyamu, aloyi wosagwira kutentha, chitsulo chosapanga dzimbiri, chitsulo chosasunthika (HRC55 ndi pamwambapa), chitsulo chakuda. |

| TU25 | Pazida zodulira zida zachitsulo (Hardness HRC45 ndi pamwambapa), chitsulo chosapanga dzimbiri, chitsulo chosapanga dzimbiri. |

| TU45 | Pazida zodulira titaniyamu, aloyi wosagwira kutentha, zosapanga dzimbiri, chitsulo chosazimitsidwa (HRC60 ndi pamwambapa) |

| TU55 | Kalasi ndi mkulu-red-kuuma, zabwino kudula zida Machining mkulu kutentha zosagwira aloyi, kuzimitsa zitsulo (HRC60 ndi pamwamba) ndi titaniyamu aloyi |

![]() Mfundo za Olimba Carbide ndodo

Mfundo za Olimba Carbide ndodo

| Kuzindikira. Ø mamilimita |

Kulolerana. (Mm) | Utali (mm) | Kulankhula. (Mm) | Ø mamilimita) | Kulolerana. (Mm) | Utali (mm) | Kulankhula. (Mm) |

| 2.0 | + 0.30 / + 0.15 | 330 | 1.5 | 16.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 2.5 | + 0.30 / + 0.15 | 330 | 1.5 | 17.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 3.0 | + 0.50 / + 0.30 | 330 | 1.5 | 17.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 3.5 | + 0.50 / + 0.30 | 330 | 1.5 | 18.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 4.0 | + 0.50 / + 0.30 | 330 | 1.5 | 18.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 4.5 | + 0.50 / + 0.30 | 330 | 1.5 | 19.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 5.0 | + 0.50 / + 0.30 | 330 | 1.5 | 19.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 5.5 | + 0.50 / + 0.30 | 330 | 1.5 | 20.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 6.0 | + 0.50 / + 0.30 | 330 | 1.5 | 20.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 6.5 | + 0.50 / + 0.30 | 330 | 1.5 | 21.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 7.0 | + 0.50 / + 0.30 | 330 | 1.5 | 21.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 7.5 | + 0.50 / + 0.30 | 330 | 1.5 | 22.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 8.0 | + 0.50 / + 0.30 | 330 | 1.5 | 22.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 8.5 | + 0.50 / + 0.30 | 330 | 1.5 | 23.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 9.0 | + 0.60 / + 0.30 | 330 | 1.5 | 23.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 9.5 | + 0.60 / + 0.30 | 330 | 1.5 | 24.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 10.0 | + 0.60 / + 0.30 | 330 | 1.5 | 24.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 10.5 | + 0.60 / + 0.30 | 330 | 1.5 | 25.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 11.0 | + 0.60 / + 0.30 | 330 | 1.5 | 25.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 11.5 | + 0.60 / + 0.30 | 330 | 1.5 | 26.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 12.0 | + 0.60 / + 0.30 | 330 | 1.5 | 26.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 12.5 | + 0.60 / + 0.30 | 330 | 1.5 | 27.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 13.0 | + 0.60 / + 0.30 | 330 | 1.5 | 27.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 13.5 | + 0.60 / + 0.30 | 330 | 1.5 | 28.0 | + 0.8 / + 0.3 | 330 | 1.5 |

| 14.0 | + 0.70 / + 0.30 | 330 | 1.5 | 28.5 | + 0.8 / + 0.3 | 330 | 1.5 |

| 14.5 | + 0.70 / + 0.30 | 330 | 1.5 | 29.0 | + 0.8 / + 0.3 | 330 | 1.5 |